Finding the Real Money Drains in Your Production

Let's be honest, when we talk about trimming production costs, the first things that pop into our heads are usually materials and labor. But in my experience, the real budget killers are often hiding in plain sight. These sneaky costs rarely show up on your regular reports, but they're constantly chipping away at your profits. Think of it like a tiny leak in your pipes – you might not notice it right away, but eventually, it’s going to cause some serious damage.

Unmasking the Hidden Culprits

So where exactly are these hidden costs lurking? Often, they’re disguised as everyday, unavoidable business expenses: things like rework from quality issues, unexpected equipment downtime, or excess inventory tying up your cash flow. These are the silent killers of a healthy bottom line.

Take equipment malfunctions, for example. One broken machine can shut down your entire production line, costing you valuable time and a hefty chunk of change. Or think about those piles of unsold products gathering dust in your warehouse. That’s money just sitting there, doing nothing for you. These aren't just minor hiccups; they're major profit drains.

Supply chain disruptions are another big one. Deloitte Insights found that a whopping 35% of manufacturers cited transportation and logistics costs as a major challenge throughout 2024 and into 2025. This just shows how quickly supply chain expenses can become a real burden. For a deeper dive into this, check out their insights here.

Conducting a Cost Audit: The Real Story

If you really want to understand how to cut production costs, a thorough cost audit is essential. I'm not talking about those polished presentations you give to the higher-ups; I mean getting down into the weeds and tracing every single dollar. It’s like conducting a forensic investigation into your finances.

This deep dive is all about identifying bottlenecks that inflate your expenses and pinpointing the areas where improvements will have the biggest impact. It requires a level of honesty and transparency that can be uncomfortable, but trust me, it's crucial for finding those areas ripe for optimization.

Let's take a closer look at some of these often overlooked expenses with a breakdown of their potential impact:

Common Hidden Production Costs and Their Impact

| Cost Category | Average Impact on Budget | Detection Difficulty | Optimization Potential |

|---|---|---|---|

| Rework due to quality issues | 5-15% | Medium | High – through improved process control and quality assurance |

| Unscheduled equipment downtime | 10-20% | Medium | High – with preventative maintenance and robust monitoring systems |

| Excess inventory | 5-10% | Easy | High – using better inventory management and demand forecasting |

| Supply chain disruptions | Variable, but potentially high | Medium | Medium – through diversification of suppliers and strategic partnerships |

| Inefficient processes | 5-15% | Hard | High – using process optimization and automation tools like Sprello |

This table highlights just how significantly these hidden costs can impact your budget. While some are easier to detect than others, they all offer significant optimization potential.

Building Your Cost Reduction Hit List

Once you’ve identified where the money is going, prioritize your efforts. Focus on the areas where you can get the biggest wins with the resources you have. Don’t try to do everything at once. Pick your battles and focus on making real progress.

A good starting point might be exploring different testing frameworks. Check out our guide on creative testing frameworks for some helpful tips. This focused approach allows you to systematically address the biggest cost drivers, maximizing your return on investment. By concentrating on these key areas, you’re building a roadmap for sustainable cost reduction and setting yourself up for long-term success.

Automation Investments That Actually Make Financial Sense

Let's face it, automation can be tricky. While it promises increased efficiency and lower production costs, it can also be a money pit if not implemented correctly. I've seen companies invest heavily in fancy new tech, only to have it gather dust. Nobody wants that.

Starting Smart with Automation

The trick is to be strategic. Don't try to automate everything at once. Instead, start small and focus on areas with the biggest potential impact. Where are your bottlenecks? What processes are truly slowing you down and eating into your profits? Those are your prime targets for automation.

For instance, if repetitive tasks like packaging or labeling are constantly tying up your workforce, a simple automated solution can free them up for more complex, higher-value work. It's all about finding the right balance between human ingenuity and technological efficiency.

Calculating the Real ROI of Automation

One common mistake I see is fixating solely on the upfront cost of automation. People forget about the hidden costs: integration, training, maintenance. These can add up quickly and torpedo even the best-laid plans.

That's why you need a solid ROI model that accounts for everything. Look beyond the initial investment to the long-term savings in labor, materials, and energy. Don't take vendor promises at face value – do your own due diligence and calculate the true ROI.

The growth in this sector is impressive. Advanced automation and robotics are transforming manufacturing and dramatically reducing costs. The global Industry 4.0 market, which includes smart manufacturing technologies, hit $114.3 billion in 2023 and is projected to grow at a CAGR of over 20% through 2032. For a deeper dive into the future of manufacturing, check out this article: Manufacturing in 2025: 10 Trends.

Avoiding Common Automation Pitfalls

Successful automation isn't just about buying the right tech—it's about implementing it the right way. This takes careful planning, employee buy-in, and continuous monitoring. Don’t skimp on training your team to use and maintain the new systems. If they aren't comfortable with the technology, you won't see the benefits. Technology should empower your workforce, not displace it. Address these critical factors upfront, and you can avoid the common mistakes that turn promising automation projects into expensive failures.

Supply Chain Redesign for Maximum Cost Efficiency

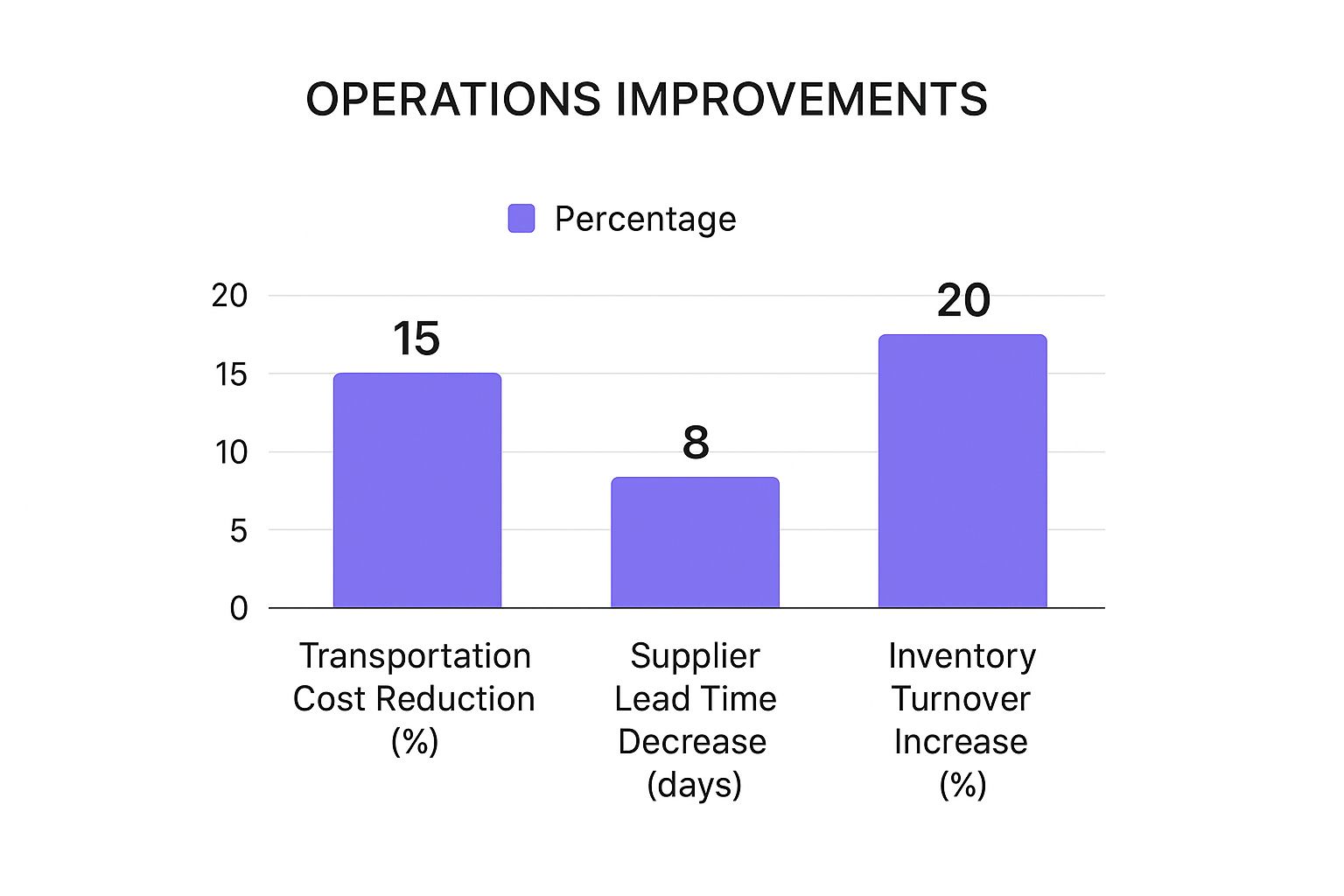

The infographic above gives you a visual snapshot of how much you can improve key supply chain metrics. Think transportation cost reduction, faster supplier lead times, and increased inventory turnover. Optimizing your supply chain can translate to serious cost savings across the board, making your operation leaner and more profitable. And these improvements often work together. For example, quicker lead times can directly impact your inventory holding costs.

Your supply chain isn't just a list of vendors; it's the backbone of your production costs. Recent global events have thrown a wrench in the works, creating both challenges and, believe it or not, opportunities. Savvy manufacturers are taking this chance to rethink their supply chains for maximum cost efficiency. This isn't about squeezing every last penny out of your suppliers, but about building real partnerships that deliver long-term value.

Diversifying Your Supplier Base

One of the smartest moves you can make is supplier diversification. Instead of putting all your eggs in one basket, spreading your procurement across multiple suppliers can protect you from disruptions and unlock cost savings. It creates a buffer against unexpected events and encourages healthy competition among suppliers. Finding reliable new partners can be tricky, though. You need a solid framework for evaluating them, focusing on quality, reliability, and of course, competitive pricing.

The Rise of Localized Manufacturing

Another trend gaining traction is localized manufacturing. Bringing production closer to your customers can drastically cut down on transportation costs and lead times. This is particularly important considering the ever-changing world of tariffs. For instance, the global tariff shifts in 2025 have forced many manufacturers to re-evaluate their sourcing strategies to keep production costs under control. In the US, we've seen baseline tariffs of 10% implemented on imports from over 100 countries, with rates climbing even higher (up to 54%) for goods from China. Want to dive deeper into this? Check out this article on the impact of tariffs on manufacturing strategy. That said, localized manufacturing isn't a magic bullet. You need to carefully weigh the potential benefits against the costs of setting up new facilities and managing a more complex production network.

Let's talk about choosing the right strategy for your business. The following table compares several approaches, outlining their initial investment, potential savings, risks, and implementation timeframes. This should help you understand the trade-offs involved and choose the best fit for your specific situation.

| Strategy | Initial Investment | Annual Cost Savings | Risk Level | Implementation Time |

|---|---|---|---|---|

| Nearshoring | Moderate | Moderate | Low to Medium | 6-12 months |

| Regionalization | Moderate | Moderate | Low to Medium | 12-18 months |

| Reshoring/Onshoring | High | High | Medium to High | 18-24 months |

| Vertical Integration | Very High | High | High | 24+ months |

| Maintaining Status Quo | Low | Low | Medium | N/A |

As you can see, each strategy presents different cost and risk profiles. While maintaining the current setup requires minimal upfront investment, it also offers limited savings potential. On the other hand, vertical integration promises significant cost reductions but entails substantial upfront investment and higher risk. Choosing the right strategy is a balancing act.

Negotiating Smarter, Not Harder

Even with your current suppliers, there are often opportunities for improvement. Negotiating better terms isn't just about haggling over price. Think outside the box and explore value-added arrangements. Could you negotiate more flexible payment terms? Are there opportunities for shared risk agreements that benefit both sides? Surprisingly, supply chain disruptions can actually be a springboard for building stronger, more mutually beneficial relationships. By getting creative and focusing on shared value, you can achieve significant cost savings without damaging your supplier relationships. Combining these strategies will help you build a more resilient, cost-effective supply chain, setting the stage for sustainable growth and profitability.

Waste Elimination Beyond the Low-Hanging Fruit

This screenshot, from the Lean Enterprise Institute's website, is a great example of the practical resources available to manufacturers. It highlights a focus on real-world application, which is exactly what you need when you're trying to actually cut costs, not just talk about it.

Everyone's always talking about eliminating waste, and most manufacturers tackle the obvious stuff. But the real goldmine of savings? It's often hidden in plain sight – the waste you might not even realize you have.

Think about it: How much energy are you bleeding away with poorly optimized equipment schedules? How much time is lost during changeovers? What about the cost of producing more than you need? That's where the real savings live. This isn't about small tweaks; it's a fundamental shift in your mindset.

Engaging Your Frontline in Waste Identification

Here's the thing: your frontline employees are the true waste-spotting ninjas. They’re in the trenches every day, dealing with inefficient processes firsthand. But too often, their voices aren't heard.

That’s a huge missed opportunity. Empower your frontline teams to identify and report waste. Imagine the cumulative impact of small suggestions, like an assembly line worker identifying a redundant step. These small wins can add up to some serious savings over time.

Real-World Examples of Waste Reduction

I've seen this in action, and the results can be impressive. One company I worked with overhauled their changeover procedures. No fancy tech, just smart process redesign. The result? They cut their changeover time by a whopping 60%.

Another manufacturer optimized their production schedule to take advantage of off-peak energy rates. The savings on their energy bill were significant. These aren’t pie-in-the-sky ideas; they're practical strategies that deliver.

Measuring and Tracking Your Progress

Okay, so you’re cutting waste – fantastic! But how do you know it’s working? You need to measure it. Track key metrics like changeover time, energy consumption, and defect rates.

Regular progress reviews are crucial. Celebrate the wins and identify areas for improvement. This keeps everyone accountable and maintains momentum. And you know what? Platforms like Sprello can even help you repurpose existing video footage to showcase those waste reduction initiatives and celebrate team successes. Talk about keeping the team motivated!

By addressing these often-overlooked areas, you can move beyond superficial cost-cutting and implement strategies that truly make a difference. Combine this with a culture of continuous improvement, and you’ve got a recipe for long-term cost efficiency and better profitability.

Smart Technology for Cost Management

Let's be honest, technology can feel overwhelming. But its real power in manufacturing isn't about replacing your team, it's about empowering them. Giving them the data and tools they need to make sharp, informed decisions. I've seen firsthand how the most successful manufacturers aren't necessarily the ones with the deepest pockets, but the ones who use technology strategically. They're focused on predicting and preventing costly problems before they even happen.

Predictive Maintenance: Stopping Breakdowns Before They Start

Picture this: a critical machine unexpectedly breaks down. Production screeches to a halt, creating bottlenecks and impacting your bottom line. It's a nightmare scenario, right? But predictive maintenance systems, powered by AI, offer a powerful solution. These systems analyze equipment data, looking for subtle clues that might indicate a future problem – weeks before it becomes a critical failure. This means you can schedule maintenance proactively, minimizing expensive downtime and getting the most out of your equipment's lifespan. Imagine catching a worn bearing weeks before it leads to a major shutdown. That's the potential of predictive maintenance.

Optimizing Inventory with Smart Tools

Too much inventory ties up valuable capital and adds to storage costs. Too little, and your production line grinds to a halt. Finding that sweet spot is crucial. Smart inventory management tools offer a way to strike the right balance. Using real-time data and predictive analytics, these tools help you maintain optimal stock levels. They can analyze historical data, sales trends, and even external factors like weather patterns to forecast demand and fine-tune your purchasing decisions. Less wasted money on excess stock and fewer production delays due to shortages? Sign me up!

Real-Time Production Monitoring: Catching Inefficiencies in the Act

Traditional reporting methods often tell you what went wrong after the fact – sometimes weeks or months later. By then, the damage is already done. Real-time production monitoring gives you instant insight into your operations, allowing you to spot inefficiencies as they occur. You're empowered to make on-the-spot adjustments, minimizing waste and maximizing productivity. It's like having a finger on the pulse of your entire production process.

Digital Twins: Testing Strategies Risk-Free

Digital twins are virtual representations of your physical assets and processes. They're like a sandbox for your operations, allowing you to simulate different scenarios and test cost-saving strategies without the risk of disrupting your real-world production. Thinking of trying a new production schedule? Simulate it first with your digital twin and identify any potential bottlenecks or inefficiencies before they impact your bottom line. You might even find the article the cost of AI video ads production interesting. This approach helps you make informed, data-driven decisions and optimize your operations with confidence.

By embracing these technologies, you're not just adopting the latest trends; you're gaining a real advantage in controlling production costs. It's about using data to make your team more effective and build a more efficient and profitable operation.

Creating a Cost-Conscious Culture That Sticks

The best way to lower production costs isn't always about fancy new equipment or software. It's about your team. When everyone cares about efficiency and reducing waste, that's where the real, lasting savings happen. But building this culture isn't about posters; it's about genuine engagement and ownership.

Empowering Employees Through Suggestion Programs

Your frontline employees are a goldmine. They see the daily inefficiencies, the clunky processes, the wasted materials. Tapping into their knowledge is key. A suggestion program that actually works needs to be more than just a box. Make it easy for employees to share ideas, and make sure they see their input is valued. When a suggestion is implemented, shout it out! Show everyone the real cost savings it achieved. This builds trust and encourages more ideas.

I remember working with a manufacturing plant where a simple suggestion from a line worker about rearranging a workstation saved the company thousands of dollars a year in wasted movement. It was a small change, but the impact was huge.

Aligning Incentives with Cost Reduction Goals

Incentive programs are great, but they can also backfire. The goal is to link individual performance with cost reduction without creating unintended consequences. For example, rewarding employees only for using less material might lead to quality issues. Instead, focus on metrics that reflect overall efficiency, like lower rework rates or better equipment uptime. This encourages a more holistic view. You might find this Sprello article on user-generated content and employee engagement interesting. It touches on similar ideas.

Transparency and Communication: The Foundation of a Cost-Conscious Culture

I've seen companies transform by being open about their financials. When employees understand how their daily work impacts the bigger picture, they're more likely to make cost-conscious decisions. Share info about production costs, profit margins, and the company's overall financial health. This creates shared responsibility.

Balancing Cost Consciousness with Innovation

While controlling costs is crucial, don't stifle innovation. You need that creative thinking for long-term growth. Encourage experimentation and continuous improvement. Sometimes a small investment in a new process or tool can lead to big long-term savings. The goal isn’t just to cut costs today, but to build a sustainable business for the future. By valuing both cost-consciousness and innovation, you’re setting yourself up for long-term success.

Your Practical Roadmap for Lasting Cost Reduction

So, you're ready to get serious about cutting production costs. Excellent! Think of this roadmap as your personalized guide, not a one-size-fits-all template. We'll walk through how to build a strategy that works for your specific situation.

Setting Realistic Targets and Tracking Progress

First things first: set achievable goals. It's great to challenge your team, but aiming for the impossible right out of the gate can be demotivating. Start small, get some quick wins under your belt, and then gradually ramp things up. It’s like working out – start with lighter weights and add more as you get stronger.

Tracking your progress is crucial, but it should be inspiring, not discouraging. Instead of broadly tracking overall spending, zero in on specific areas. Think rework costs, equipment downtime – metrics that give you a real sense of where you’re making an impact.

Actionable Tools for Cost Analysis and Automation

Now for the practical stuff. Templates for cost analysis can be a lifesaver, giving you a structured way to pinpoint your biggest expense areas. Checklists for automation readiness? These can help you figure out which processes are actually good candidates for automation, saving you from costly missteps. And don’t forget frameworks for evaluating new cost-saving ideas – they’ll keep you flexible and proactive.

These resources empower you to make decisions based on solid data, not guesswork. They provide the structure and clarity you need to navigate the often-complex world of cost reduction.

Maintaining Momentum and Building a Cost-Conscious Culture

Here's the most important thing to remember about cutting costs: it’s a marathon, not a sprint. There will be times when things slow down. That’s perfectly normal. The key is to stay focused on the long term and build a culture where everyone’s on board with controlling costs. This means empowering your employees to spot waste and suggest improvements.

By weaving cost-consciousness into your company’s DNA, you’re not just cutting costs, you're building a more resilient and successful business for the long haul.

Ready to take your cost reduction efforts to the next level? Sprello can help you repurpose existing video content to highlight successes, celebrate team wins, and keep everyone engaged on the cost-saving journey. Transform your cost reduction initiatives from a one-off project into a continuous process.